NEWSROOM

Blog

[Movensys Column] Beyond Hardware: Redefining the Future of Industrial Equipment Control Through Software (JeeGwang Heo, CTO of Movensys)

- 2025.06.25

- |

- 최고관리자

- |

- 1,923

Perspectives on technology, system design methodologies, and the surrounding ecosystems are undergoing comprehensive transformation.

While discussions on whether to choose PLC or PC-based control methods continue on the field, the question is increasingly shifting toward a more fundamental concern.

Beyond simple performance comparisons between controllers, the core essence lies in how flexible, intelligent, and scalable the control system can be across the entire process. In this context, PC-centric control methods are emerging as the most suitable and powerful alternative to adapt flexibly to such changes.

1. Changes in the Educational Environment: The Language of Control is Changing

Recently, automation education in universities and vocational training institutions shows a distinctly different trend from the past.

Previously, control practice was centered on hardware-based systems using ladder diagrams. Now, courses mainly involve implementing control simulations using general-purpose programming languages such as Python and C++.

Not only has the language changed, but the entire approach to understanding and learning control technology is shifting to a PC-centric.

Students are becoming more accustomed to designing control systems and solving problems through API integration, algorithm implementation, and virtual simulation, rather than physical hardware wiring. The background for this shift includes the following reasons:

- High usability of general-purpose development tools: Powerful environments like Visual Studio, Eclipse, and PyCharm effectively support debugging, testing, and deployment.

- Easy accessibility of programming languages: Python and C-based languages are already familiar to engineering students, lowering the barrier to learning.

- Wide applicability of general-purpose languages: PC-based practice naturally connects to IT convergence technologies such as vision recognition, AI, and big data.

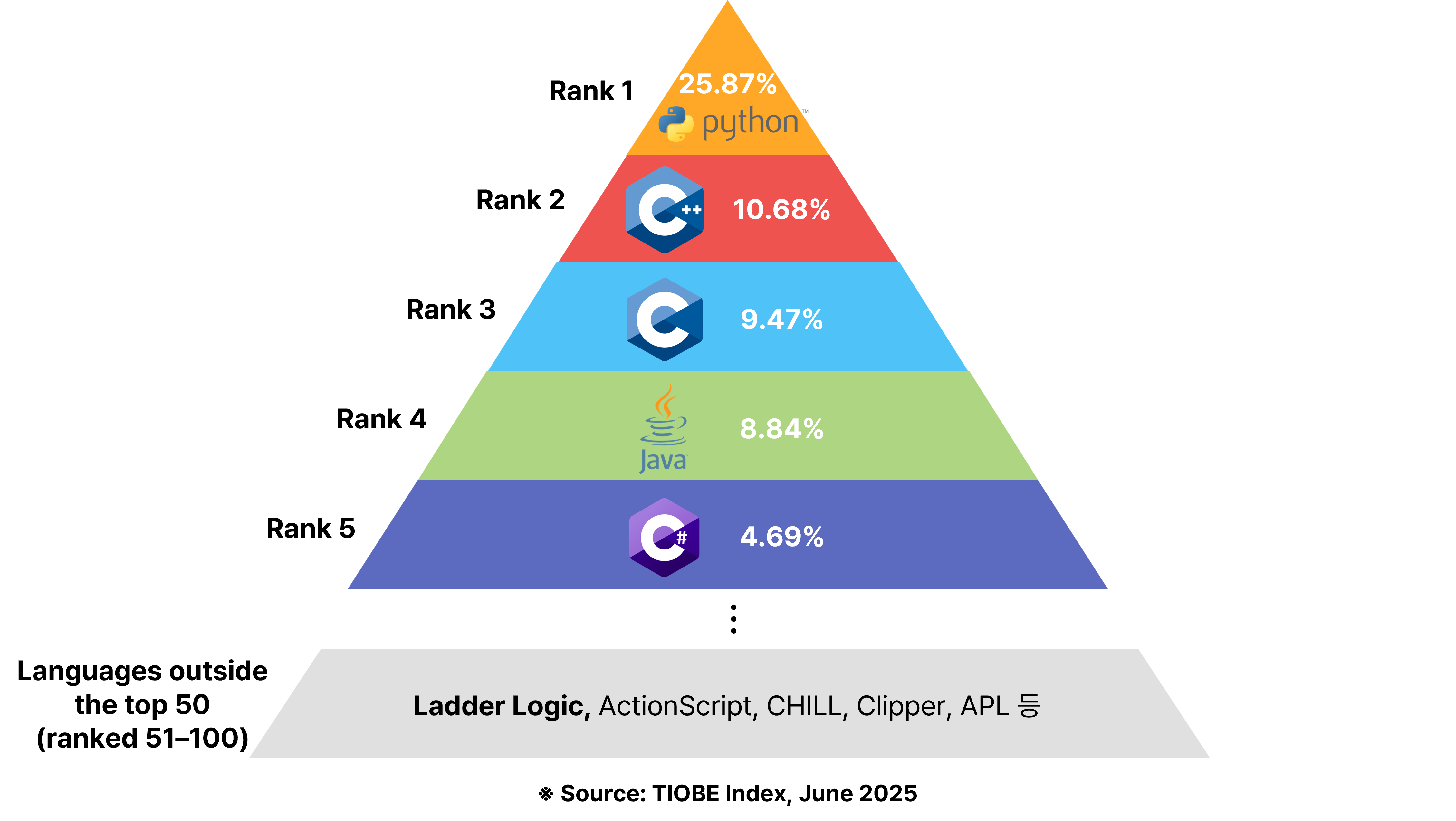

Figure 1. Global Programming Language Popularity Rankings as of June 2025

As shown in Figure 1, such education based on general-purpose programming languages broadens students’ opportunities to enter various software development fields in the future, aligning well with the practical competencies demanded by the industry. As a result, future control engineers are becoming more familiar with PC-based system design than with traditional PLC-focused education.

2. Transitioning from PLC to PC-Based Controllers—Is It Possible?

PLCs have long been the industry standard due to their reliability and stability, and they still hold a significant portion of the market.

However, as processes become more advanced and equipment logic more complex, cases of transitioning to PC-based controllers are steadily increasing.

For example, a company developing semiconductor back-end process equipment adopted Soft Motion(PC-based motion controller) for the following reasons:

- To improve processes through real-time data analysis

- Because existing PLCs had separated control logic and data processing systems, making maintenance complex

- Because new engineers were already familiar with C-based languages and could quickly adapt to the development environment

Semiconductor back-end equipment involves highly complex logic and often requires dynamic operation depending on various conditions. Implementing and debugging tens of thousands of lines of logic with ladder language in PLCs is inevitably inefficient.

In contrast, Soft Motion has modular structures, excellent debugging capabilities, and real-time data processing, enabling much more effective management of complex sequences.

This company redefined the equipment logic through software over a six-month transition and has since optimized processes solely through software updates—without changing the equipment itself.

Of course, PLCs cannot be completely replaced in every environment at present. However, in environments that require AI integration, real-time analysis, and flexible logic implementation, PC-based controllers demonstrate far greater competitiveness.

3. Expansion of Technology: Seamless Integration Between Controllers and IT Technologies

Today’s industrial equipment control goes beyond simply driving machinery. Advanced requirements such as predictive maintenance, digital twins, and cloud monitoring demand that controllers be capable of organically integrating with various IT (Information Technology) technologies.

A recent client requested the application of Google’s gRPC-based communication protocol to our controller. While such an implementation would have been nearly impossible with a traditional PLC architecture, it was successfully completed on Soft Motion in just two months, with a basic understanding of the protocol and some coding effort.

With the adoption of gRPC, fast and reliable bidirectional communication with the host system became possible without the need for a separate TCP/IP protocol definition or communication module. It also enabled a flexible environment for data collection and command control without complex customization.

Furthermore, future visions of smart factories—such as AI-based process optimization, high-speed vision analysis, and cloud-based remote monitoring—can only be realized when controllers allow for flexible data handling.

PLCs are designed with fixed functions and prioritize process sequence stability, which inherently limits their compatibility with IT convergence technologies in both structural and functional aspects.

Advanced industrial control is evolving in a direction that offers high added value—such as equipment performance verification, process improvement, and yield enhancement—through digital twins and cloud-native technologies.

This forms the basis for operational competitiveness not only for equipment manufacturers but also for end users such as Samsung Electronics and SK Hynix.

PLCs will continue to play an important role in areas such as plants and process lines, where operations may be relatively simple but absolute stability is essential.

However, the transition to PC-centric control technologies in education, manufacturing sites, and the overall technology ecosystem is a fundamental trend.

It is now time to move beyond the question of “what to control with” and start asking “how to build a more flexible and intelligent control system.”

PC-based controller, cloud infrastructure, and AI integration technologies can be the most effective answers to this new standard.

The future of industrial control will not be confined by hardware.

By redefining structures to adapt to changing environments and organically connecting people, technology, and data, PC-centric and flexible control platforms will be at the center of industrial evolution.

- Contributor: JeeGwang Heo, CTO of Movensys

Previous

Previous

Next

Next