NEWSROOM

Blog

[Movensys Column] The Future of AMR Technology: How Human-Aware Navigation is Transforming Industrial Automation (Kota, CTO of Skylla)

- 2025.10.10

- |

- 최고관리자

- |

- 2,370

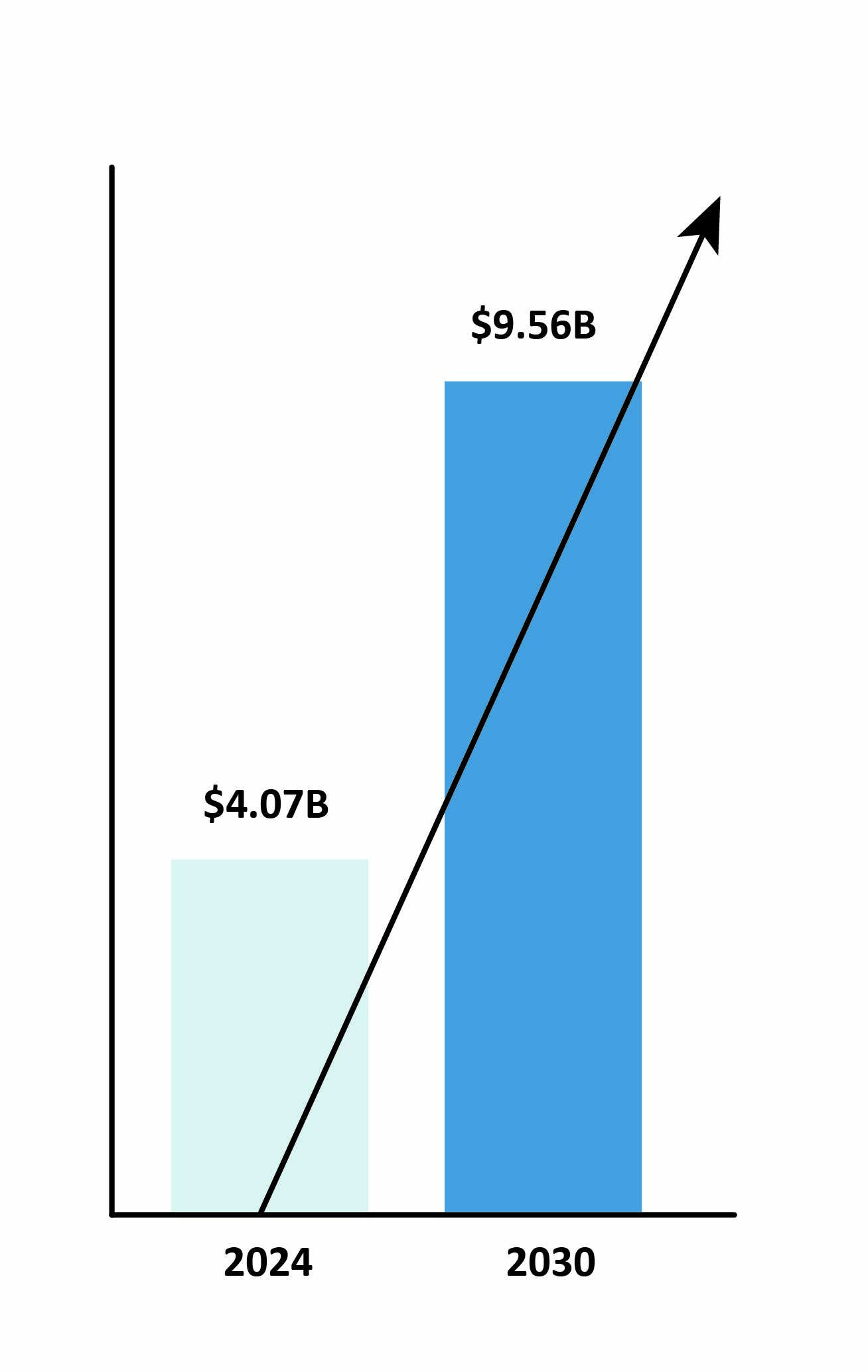

The autonomous mobile robot (AMR) industry is experiencing unprecedented growth, with market projections showing expansion from $4.07 billion in 2024 to $9.56 billion by 2030. (Figure 1) Behind these impressive numbers lies a fundamental technological shift that's reshaping how robots navigate and interact in industrial environments.

Most AMR systems today struggle with one critical challenge: seamlessly working alongside humans. Traditional robots treat people as obstacles to avoid, creating inefficiencies and limiting their deployment potential. Human-aware navigation technology is changing this dynamic entirely, revolutionizing everything we thought we knew about industrial robotics.

Figure 1. Market Growth Outlook for Autonomous Mobile Robots (AMRs): USD 4.07 billion in 2024 → USD 9.56 billion in 2030

※ Source: Grand View Research, Autonomous Mobile Robot Market Size | Industry Report 2030.

Beyond Obstacle Avoidance: The Navigation Revolution

Traditional AMR navigation systems operate on a deceptively simple principle: detect obstacles and avoid them. While this approach works reasonably well in static environments, modern industrial facilities are anything but static. They're dynamic spaces where humans and robots must collaborate efficiently throughout the day, often in tight quarters with constantly changing priorities.

Figure 2. Example of a conventional AMR stopping after recognizing a human as an obstacle

When a traditional AMR encounters a person, it stops and waits. Sometimes it attempts to navigate around them, but often it simply sits there until the path clears. (Figure 2) Entire production lines can slow down because workers must constantly step aside to let robots pass, or worse, wait for robots to figure out their next move. This defeats the purpose of automation and creates frustration for everyone involved.

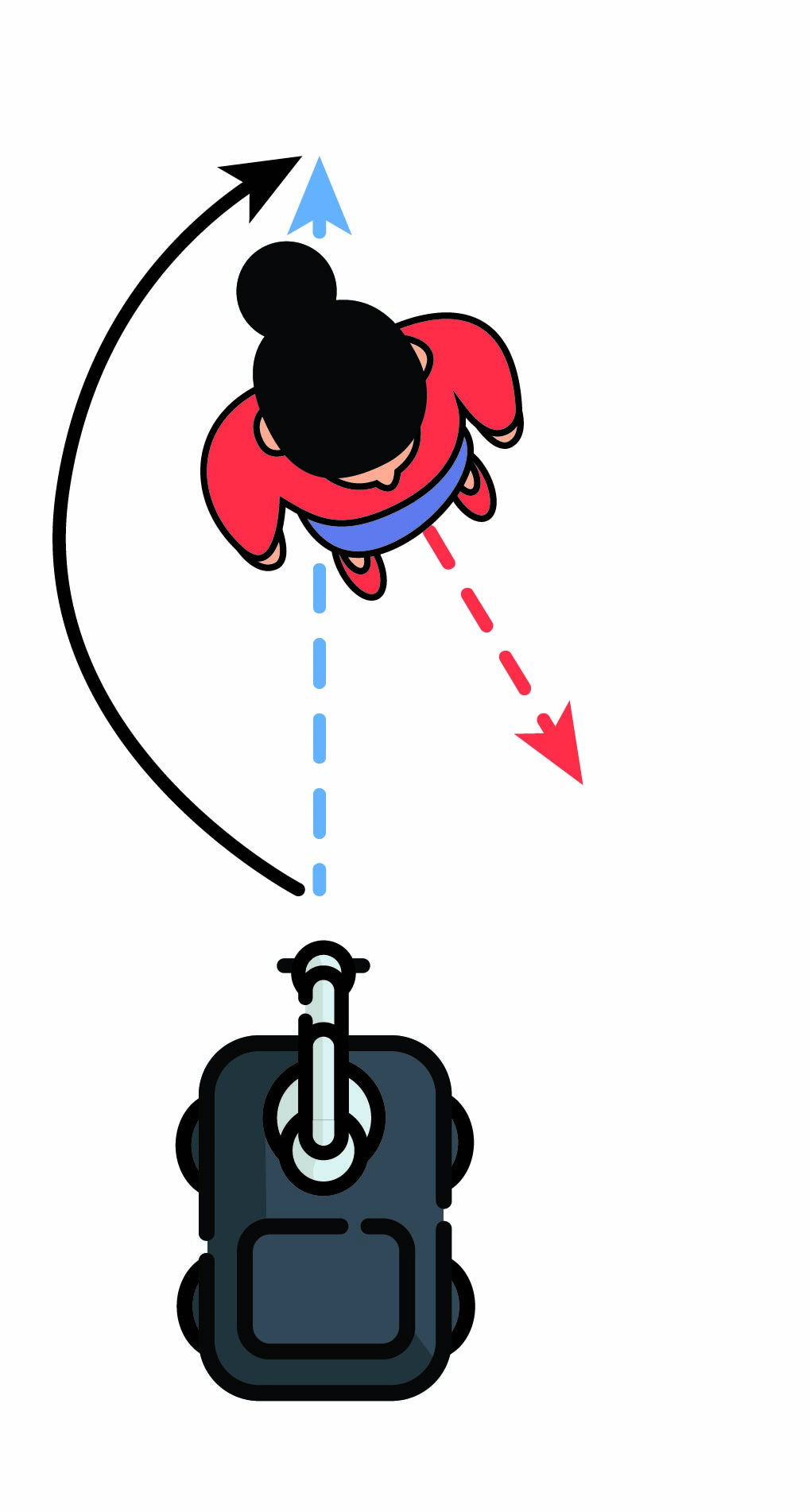

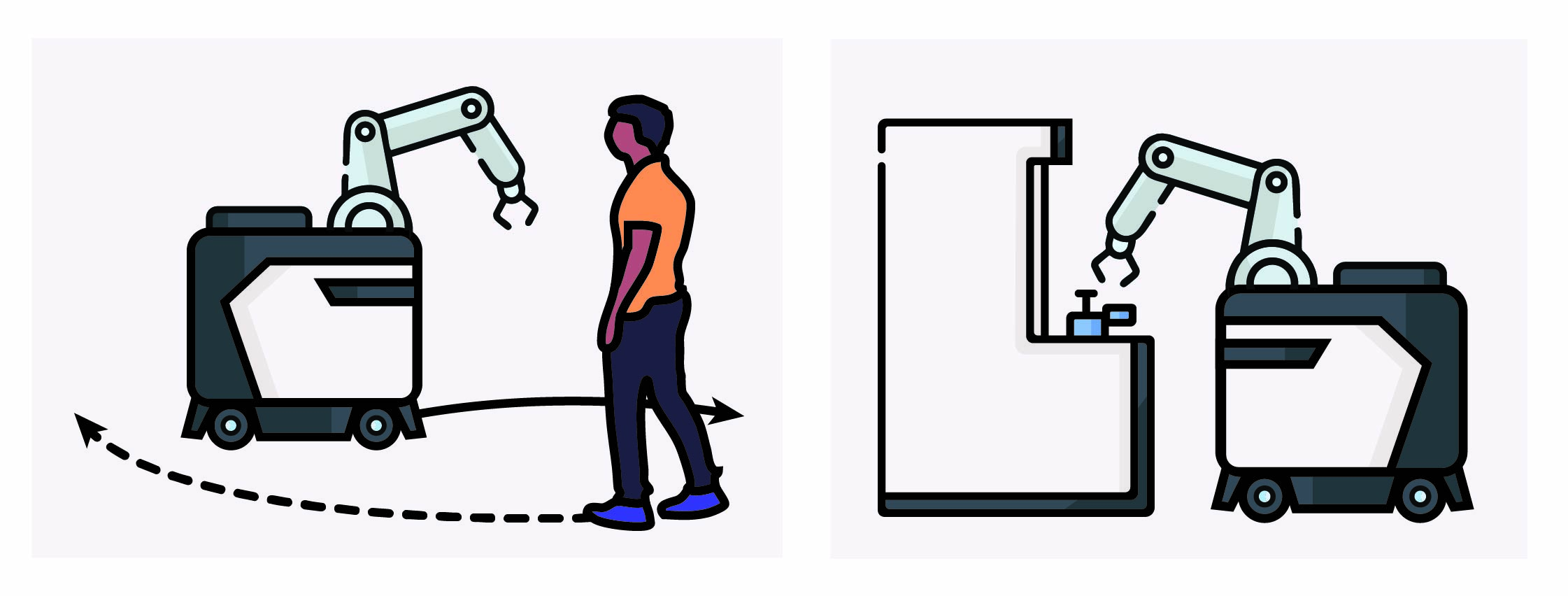

Figure 3. Example of a human-aware AMR flexibly avoiding collisions by predicting human movement

Human-aware navigation takes a fundamentally different approach. Instead of treating humans as obstacles, these systems understand human behavior patterns, predict movement intentions, and adapt their navigation accordingly. (Figure 3) This creates a seamless collaboration environment where robots work continuously alongside human operators without the constant stop-and-start dance that has become synonymous with traditional AMR deployments.

The technology behind this transformation is sophisticated yet elegant. Advanced sensor fusion combines LiDAR environmental mapping with RGB-D cameras for human detection and behavior analysis. Machine learning algorithms, trained on thousands of hours of real-world industrial data, enable predictive modeling of human movement patterns. The result is robots that move naturally through crowded spaces while maintaining the precision and safety standards that industrial applications demand.

AMR Navigation vs. Autonomous Driving: Completely Different Challenges

There's a persistent misconception that AMR navigation is simply autonomous driving technology adapted for indoor use. The reality is far more complex.

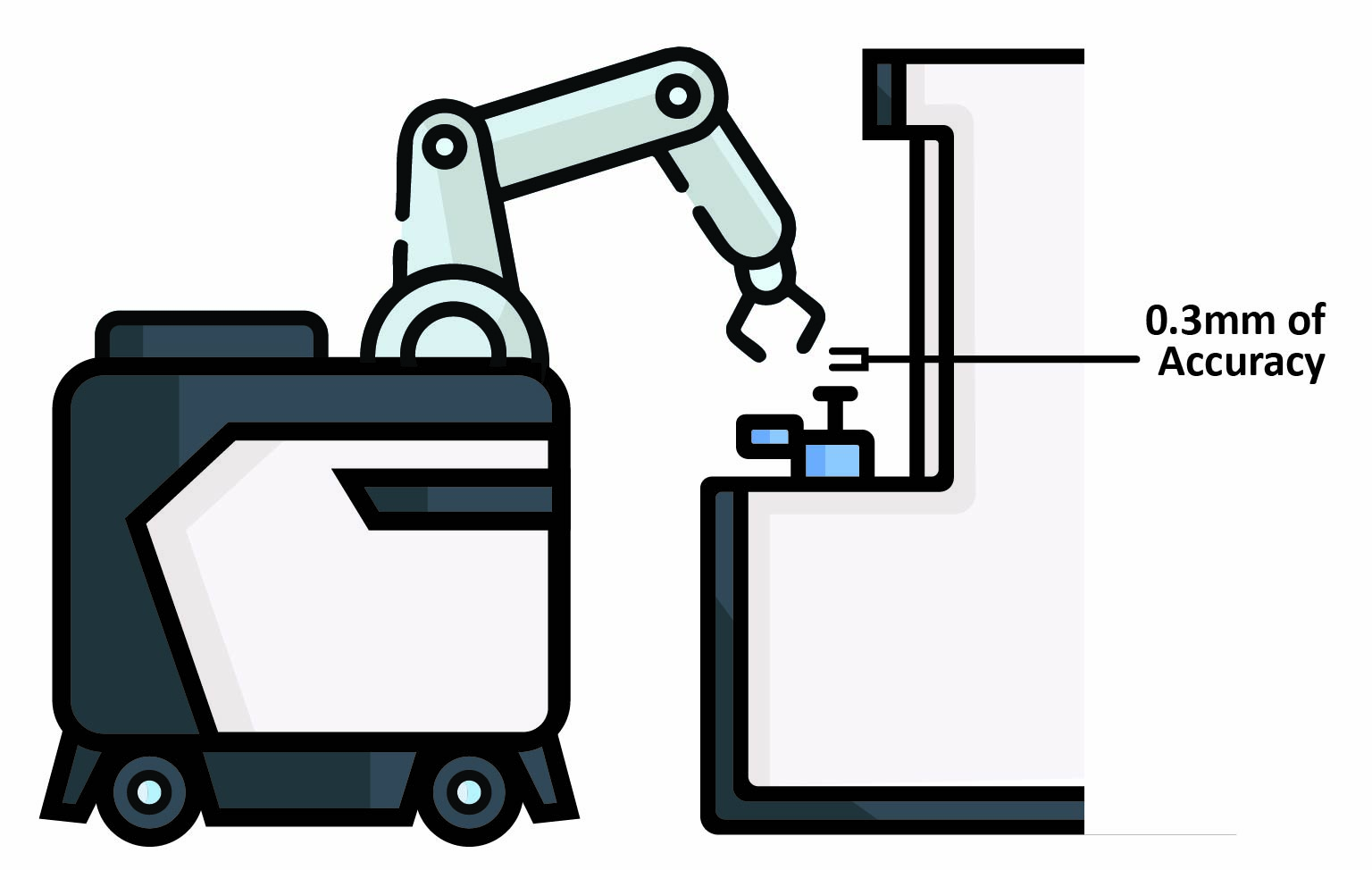

Figure 4. Example of an AMR performing high-precision operations with 0.3 mm docking accuracy

The precision requirements alone tell a compelling story. AMRs need millimeter level precision for tasks like machine loading and precise material handling. The best systems today achieve vehicle docking accuracy of a few millimeters, roughly 100 times more precise than what autonomous vehicles require for lane keeping. (Figure 4) Further, robotic endpoint positioning accuracy can be well within a millimeter. When docking with a CNC machine or positioning materials for precision assembly, this level of accuracy isn't just helpful – it's absolutely essential.

Environmental challenges add another layer of complexity. Autonomous vehicles navigate structured roads with GPS assistance and relatively predictable traffic patterns. AMRs operate in indoor environments without GPS signals, building and maintaining detailed maps using onboard sensors while adapting to constantly changing layouts. Imagine navigating a house where the furniture moves around randomly throughout the day, and the challenge becomes clear. There are some global localization methods used within factories, but most do not have the level of accuracy, responsiveness, or operating range required to drive AMRs. In addition, these types of systems can be prohibitively expensive when spanning a factory.

Most importantly, AMRs must collaborate with humans in shared workspaces. Autonomous vehicles primarily follow traffic rules and avoid collisions. They don't need to understand that a person walking toward them is carrying a heavy load and might need extra space, or recognize that someone's body language indicates they're about to change direction. These subtle human behaviors are crucial for effective collaboration in industrial settings.

Market Forces Driving Widespread Adoption

The numbers driving this transformation tell a compelling story. Industry analysts expect 70% of manufacturing plants worldwide to deploy AMRs by 2030, while the warehouse automation market alone is projected to reach $45 billion. Labor shortages across industries are creating urgent automation needs that traditional approaches simply cannot address.

However, successful AMR deployment depends on more than just having robots in facilities. It requires robots that can work effectively alongside human teams without disrupting established workflows. This is where human-aware navigation becomes the critical differentiator between successful implementations and expensive failures.

Too many facilities have experienced traditional AMRs creating more problems than they solved. Workers develop workarounds to avoid interfering with robots, production schedules get disrupted by navigation failures, and management loses confidence in automation technology. Human-aware systems avoid these pitfalls by integrating naturally into existing workflows, actually enhancing human productivity rather than fighting against it.

Industry Applications: Where This Technology Excels

Figure 5. AMR performing precise assembly or predictive avoidance movements in manufacturing environments

Manufacturing environments showcase human-aware navigation at its best. In these facilities, precision and human collaboration are paramount. Advanced navigation enables AMRs to support assembly lines, handle material transfers, and assist with machine loading while adapting to human operators' work patterns. The robots learn the rhythm of the facility and adjust their behavior accordingly. (Figure 5)

Modern warehouses and distribution centers present another compelling use case. These dynamic environments require humans and robots to work together efficiently, especially during peak periods like holiday seasons. Human-aware navigation enables continuous operation even when facilities are crowded with temporary workers and heightened activity levels.

The high-tech sector, such as the semiconductor market, has embraced this technology for industries requiring extreme precision and contamination control. Modern mobile manipulators, AMRs with robot arms, operate with sub-millimeter accuracy while maintaining clean operation standards – a combination that was impossible with earlier generations of AMR technology.

Public and transportation spaces represent perhaps the most challenging application. Airports, railway stations, and shipping terminals present complex navigation challenges with unpredictable human traffic patterns. The fact that advanced systems can operate safely and efficiently in these demanding environments demonstrates just how far the technology has progressed.

Looking Toward the Future

Figure 6. Examples of human–robot interaction through multimodal interfaces such as voice, gestures, drawings, and natural language

The trajectory of AMR technology development is accelerating rapidly. The next generation will be built from the ground up with artificial intelligence, enabling continuous learning and adaptation. These systems will improve their performance over time, learning from each interaction and environment. Robots will get better at their jobs every day, automatically adapting to seasonal changes in workflow and optimizing routes based on historical data.

Enhanced sensor fusion is creating comprehensive environmental understanding that goes far beyond today's capabilities. Advanced sensor combinations including thermal cameras, 3D vision systems, and passive cameras are providing robots with almost human-like perception of their surroundings. (Figure 6)

Of course, it’s hard to discuss AMRs without mentioning the development of humanoid robotics. While it is easy to assume there is great overlap in usage, humanoids still have severe limitations surrounding battery life, max payload capacity, and costs due to system complexity. The resources invested in humanoid robotics development is resulting in improved controls, actuator, battery, and sensor technologies all of which can further benefit the AMR space. To some degree, we are also seeing a convergence of the technology; some AMRs now carry two robot arms designed to behave similarly to the upper half of a humanoid robot. Regardless of where that technology goes, it seems only natural that we will be seeing AMRs and humanoid robots developed to work collaboratively in the near future.

The Transformation Ahead

The AMR industry stands at a critical turning point. Traditional navigation approaches that treat humans as obstacles are rapidly giving way to collaborative systems that understand and work with human patterns. This represents more than technological advancement – it's a fundamental shift toward truly collaborative robotics that will define the next decade of industrial automation.

Human-aware navigation technology is already proving its value in demanding industrial applications across sectors from precision manufacturing to public transportation. Systems that understand human behavior and adapt accordingly consistently demonstrate superior performance in real-world deployments.

As the market grows, competitive advantage will increasingly depend on successful integration of robots into human workspaces. Human-aware navigation isn't just another feature – it's becoming the foundation of successful automation in modern industrial environments.

The technology has matured beyond proof-of-concept stages. The market opportunity is clear and quantifiable. The benefits are measurable and substantial. The question facing organizations today isn't whether human-aware navigation will transform industrial automation, but how quickly they'll adopt this technology to gain competitive advantage in an increasingly automated world.

Investment in human-aware navigation represents more than equipment acquisition – it's strategic positioning for the future of manufacturing and logistics. Early adopters are establishing competitive advantages that will compound as the technology becomes standard across industries. The transformation is already underway, and the companies that embrace it first will be the ones that define the future of human-robot collaboration.

- Contributor: Kota, CTO of Skylla

Previous

Previous

Next

Next